In today’s pandemic situation, gas prices have been reaching its highest and lowest prices in the last two decades. With only private vehicles allowed to travel, who is brave enough to pump gas these days?

The coronavirus is rapidly spreading around from the smallest region to the biggest nation. Its virus could live anywhere from simple doorknobs to even a surface as grimy and inconsistently cleaned as the gas pump in your nearest gasoline stations.

But even before this pandemic crisis, according to a 2011 study by personal hygiene company Kimberly-Clark, the handles of gasoline pumps were found to be the filthiest of any surface out there. It comes to the fact that nobody cleans the things that you’re touching on a daily basis.

It’s a reality of life in a car-commuting corridor such as your nearest service station, a visit to your fuel pumps every week or two.

Since we are now in a pandemic situation, how do you do it safely knowing that coronavirus can live on surfaces for hours if not even days?

Here in our country, the attendants are the ones holding the nozzle and fill-up the var for our cars. In this case, making communication between the customer and the attendant is what we keep in mind. Wearing a face shield or a face mask when talking to service station attendants is your safest bet to ensure the virus is not passed from attendants to customers and vice versa. But for more safest tips, here are some reminders to always keep in mind:

- Have disinfectant wipes ready whenever you receive your change or your card to simply wipe off the germs.

- Isolate yourself from touching the keypad when entering payment information.

- Use hand sanitizers or sprayed alcohol to clean your hands before and after you’re done and before going into your car.

Keep in mind to not only protect yourself from the gas pump, but also from the keypad. It’s a good idea to have a roll of paper towels, disinfectant wipes, hand sanitizers, and alcohol, or even a box of latex gloves in your trunk for those trips to the pump.

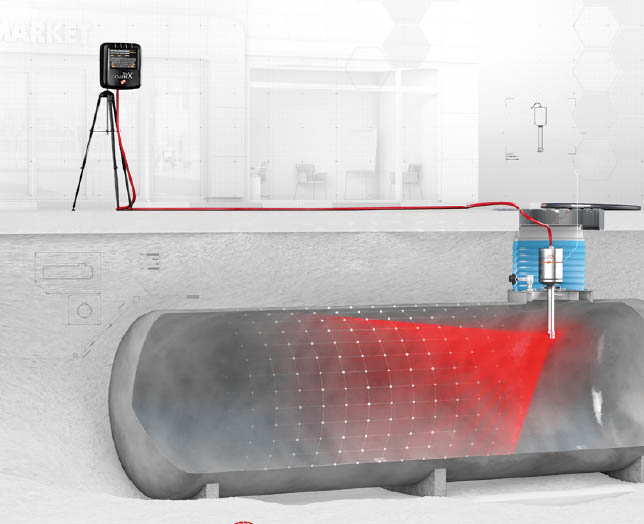

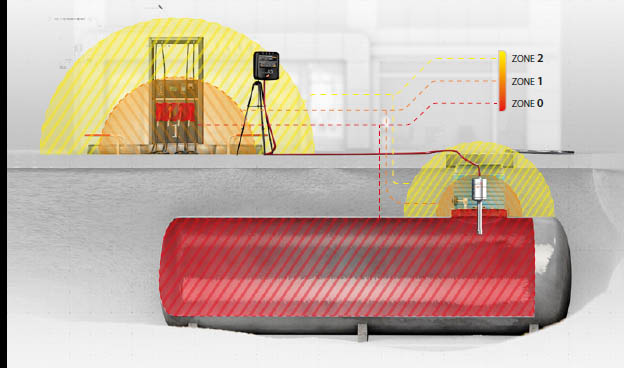

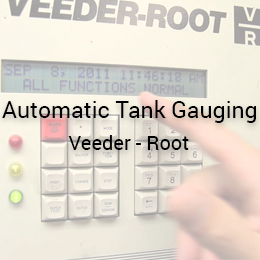

Gasoline service stations are one of the most visited service station businesses out there for your vehicle needs. Along with most visitors comes a lot of people touching those pumps every single day. For safer and cleaner equipment, TOIC Solutions offers high-quality fuel pumps and dispensers as we are the exclusive distributor of Gilbarco Veeder-Root in the country. Gilbarco Veeder-root is the global leader in fuel dispenser technology and integrated fueling solutions, from the forecourt to the c-store. To know more about our wide range of service station equipment, contact us for more information.